Wear

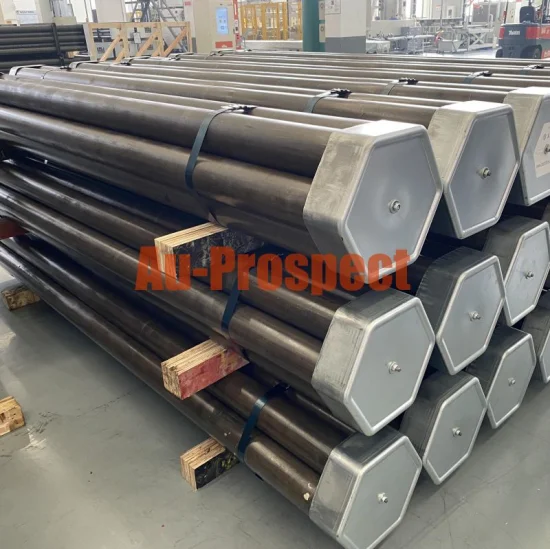

Hammer head: Commonly used nicknames: hammer head, wear-resistant hammer head, high chromium cast iron composite hammer

Description

Basic Info.

| Model NO. | lx-8000117 |

| Material | Alloy Steel |

| Maganese | Maganese |

| Transport Package | Steel Pallet |

| Specification | 5ton |

| Trademark | Rock Rubble |

| Origin | China |

| Production Capacity | 300ton/Year |

Product Description

Hammer head:Commonly used nicknames: hammer head, wear-resistant hammer head, high chromium cast iron composite hammer head, high chromium composite hammer head, hinged hammer head, hammer crusher wear-resistant hammer head

Main material: high chromium cast iron Gr20 and wear-resisting alloy steel, high chromium cast iron Gr26 and wear-resisting alloy steel

Manufacturing process: lost mold casting, quartz sand casting, resin sand casting

Applicable materials: pulverized coal, coal gangue, limestone, shale, feldspar, gypsum, coke, brick, limonite, gravel, salt and sulfur, phosphate ore, etc

Application: used in coal, metallurgy, building materials, chemical, electric power and other departments of crushing or fine crushing production operations

Product features: Support to map to sample processing or site drawing, according to the needs of customization

Product Introduction:

Hammer crusher working principle, for the motor driven with a hammer head rotor high-speed rotation, hammer crusher hammer and rotor disc hinged connection, through the high-speed rotation of the rotor hammer to produce centrifugal impact on the material, shear, grinding effect; In the lower part of the rotor, is provided with a sieve plate, pulverized materials smaller than the size of the sieve sieve through the size of the particle discharge, greater than the size of the coarse particle resistance to stay on the sieve plate continue to be hit and grinding hammer again, finally discharged through the sieve plate machine.

The vulnerable parts of hammer crusher are composed of hammer head, counterattack lining plate, rotor disc, pin, and sieve plate, etc.

My company has many years of experience in production and sales of composite hammer crusher, the use of special compound casting technology in manufacturing, hammer head struck parts with high chromium cast iron wear materials, hammer handle parts adopt impact toughness good wear resistant alloy steel material, through fission inlay compound casting method, ensure the composite hammer with high chromium wear resistance and impact toughness of the mechanical properties, Compared with manganese steel hammerhead, the service life of the hammerhead produced by our company can be increased 3-5 times.

Contact us today and we will deliver an accurate casting quote within 2 working days!

Jaw crusher wear parts. There are two jaw plate in one jaw crusher. One called fixed jaw, the other called swing jaw. They work together to make the stones get into small pieces.

Material: High Manganese--

Mn20Cr3

Mn18Cr2

Mn13Cr2

Mn13

...

MOQ:1 piece

delivery package steel pallet

Production technology: casting & water quenching & machining

Surface process: shot blasting & painting & oil

Size: according customer's drawing or model no.

Prev: Factory Supply Casting Hammer Crusher Parts Wear Resistant Mining Rock Hammers for Crusher

Next: High Hardness Alloy Crushing Hammer, Breaking Hammer, Wear

Our Contact

Send now